From Iron Ore To Steel In A Blast Furnace. It is a very lengthy and. Ash from the coke is absorbed by the slag. Historically the sizes of iron ore sent to the blast furnace have been varying as the advantage of close sizing was gradually realized. Iron ore is reduced to iron by heating them with coke a form of carbon in blast furnace.

Iron And Steel

Iron And Steel From chemguide.co.uk

Iron And Steel

Iron And Steel From chemguide.co.uk

More related: Great Wall Express Rosecrans - G La Dalle Champs Sur Marne - Cambiare L Ora Lancia Y - Eh Holden Wagon Interior -

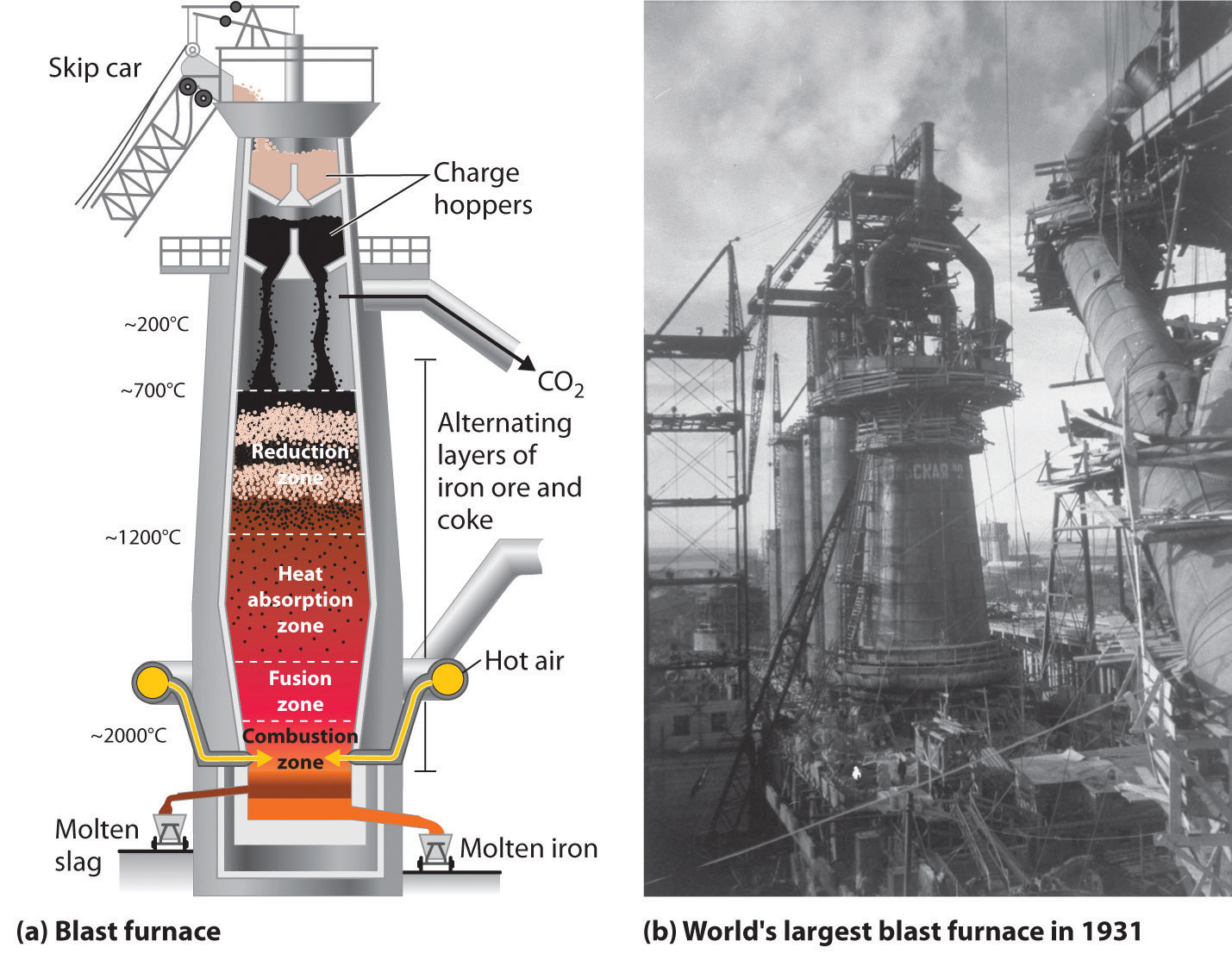

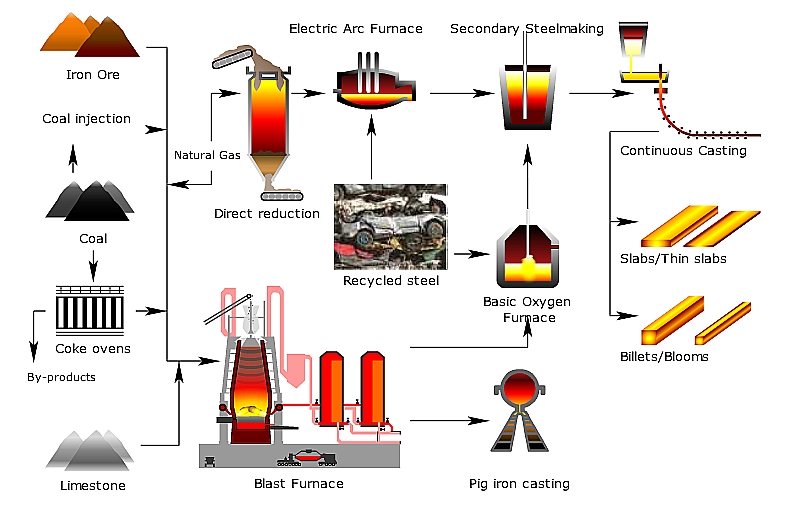

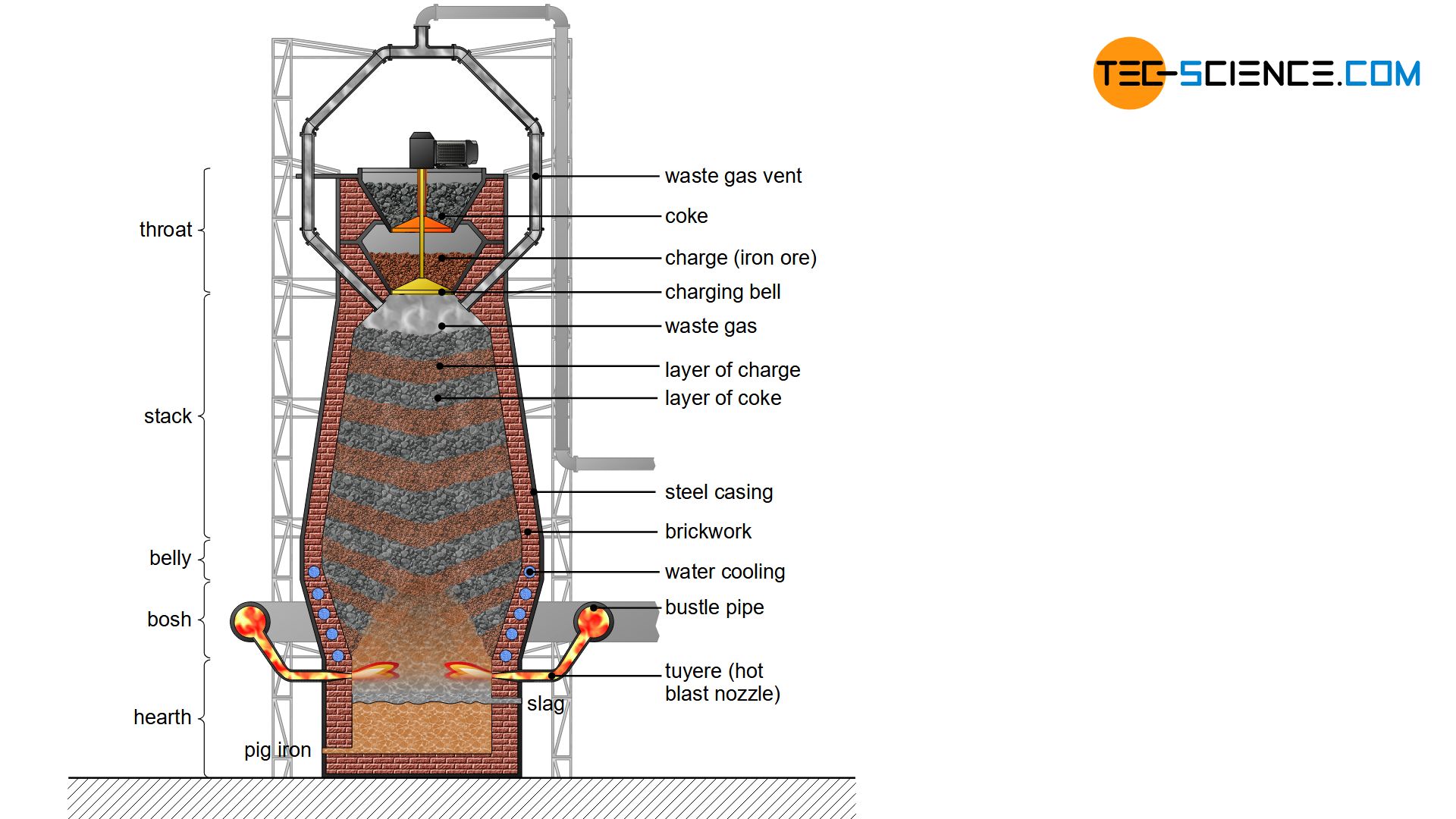

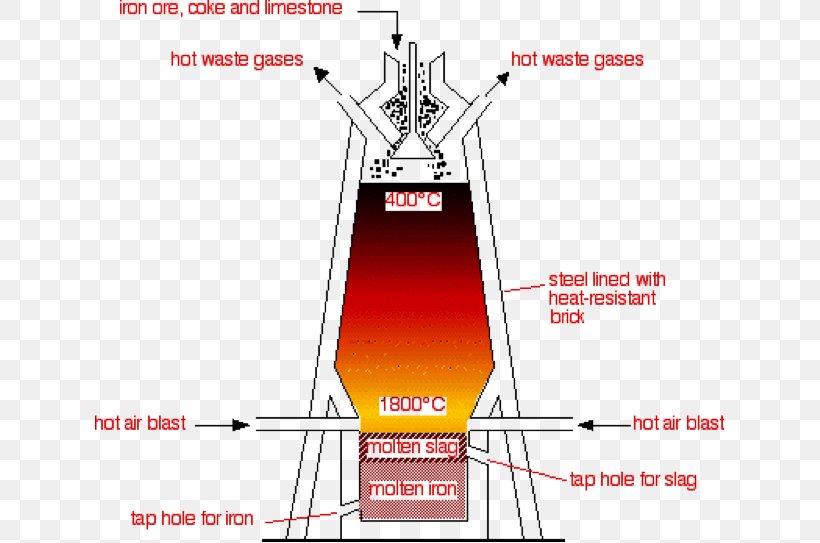

We see this in photos as a huge furnace system and it involves multiple components. In this reaction the ironIII oxide is reduced to iron and the carbon is oxidised to carbon dioxide. The iron is extracted from its oxide ore called Hematite. The combustion of iron ore with other materials in the blast furnace produces molten pig iron which is then converted to steel. Back to making steel. This rock-like or earthy substance is called iron ore.

However this metal does not exist as a pure element in nature but only in chemical compounds for the most part in an oxygenated form.

Blast furnaces differ from bloomeries and reverberatory furnaces in that in a blast furnace flue gas is in direct contact with the ore and iron allowing carbon monoxide to diffuse into the ore and reduce the iron oxide. So iron is not converted into steel in the blast furnace. The molten iron from the blast furnace which would be pig iron if it were cooled and solidified is converted to steel by selectively oxidizing excess carbon. Due to the reduction of the solidificatoin point by diffused carbon into the reduced iron it begins to melt in the hotter zones of the blast furnace. To make steel iron ore is first mined from the ground. The iron is extracted from its oxide ore called Hematite.

Steel Production From Iron Ore To Functional Industrial Products

Source: vepica.com

Steel Production From Iron Ore To Functional Industrial Products

Source: vepica.com

The blast furnace Iron ores such as haematite contain ironIII oxide Fe 2O 3.

Blast Furnace Wikipedia

Source: en.wikipedia.org

The result from both is liquid iron which is then transported to the basic oxygen furnace.

Blast Furnace Furnace Metal Working Tools

Source: pinterest.com

Blast Furnace Furnace Metal Working Tools

Source: pinterest.com

To make steel iron ore is first mined from the ground.

23 3 Metallurgy Of Iron And Steel Chemistry Libretexts

Source: chem.libretexts.org

23 3 Metallurgy Of Iron And Steel Chemistry Libretexts

Source: chem.libretexts.org

Coke is utilized to melt the iron ore to create pig iron.

Iron Ore To Steel Process Flow Chart Tifom

Source: tifom.unionadfp.org

Iron Ore To Steel Process Flow Chart Tifom

Source: tifom.unionadfp.org

Extraction of iron happens in the blast furnace.

Iron And Steel

Source: chemguide.co.uk

Iron And Steel

Source: chemguide.co.uk

This page looks at the use of the Blast Furnace in the extraction of iron from iron ore and the conversion of the raw iron from the furnace into various kinds of steel.

The Iron Ore Based Steelmaking Download Scientific Diagram

Source: researchgate.net

The Iron Ore Based Steelmaking Download Scientific Diagram

Source: researchgate.net

Oxygen is then used to transform the pig iron into steel.

The Production Of Iron And Steel The Blast

Source: slidetodoc.com

The Production Of Iron And Steel The Blast

Source: slidetodoc.com

The path from iron ore to steel and the path from scrap to steel.

5 4 Describe And Explain The Main Reactions Involved In The Extraction Of Iron From Iron Ore Haematite Using Coke Limestone And Air In A Blast Furnace Igcse2016

Source: igcse2016.wordpress.com

5 4 Describe And Explain The Main Reactions Involved In The Extraction Of Iron From Iron Ore Haematite Using Coke Limestone And Air In A Blast Furnace Igcse2016

Source: igcse2016.wordpress.com

Historically the sizes of iron ore sent to the blast furnace have been varying as the advantage of close sizing was gradually realized.

Ash from the coke is absorbed by the slag.

2

Source:

The molten iron from the blast furnace which would be pig iron if it were cooled and solidified is converted to steel by selectively oxidizing excess carbon.

Picture Blast Furnace Furnace Castle Plans

Source: pinterest.com

Picture Blast Furnace Furnace Castle Plans

Source: pinterest.com

Reduction of iron ore in the form of lumps pellets or fines to iron by a reducing gas or elemental carbon produced from natural gas or coal.

Production Routes For Steel

Source: sustainableinsteel.eu

Production Routes For Steel

Source: sustainableinsteel.eu

From iron ore to steel in a blast furnace flow diagram.

Ironworks Tec Science

Source: tec-science.com

Ironworks Tec Science

Source: tec-science.com

At the same time excess.

Pig Iron Blast Furnace Route International Iron Metallics Association

Source: metallics.org

About halfway down limestone begins to react with impurities in the ore and the coke to form a slag.

Blast Furnace Metallurgy Britannica

Source: britannica.com

Blast Furnace Metallurgy Britannica

Source: britannica.com

Limestone is added to the blast furnace to capture impurities and.

Blast Furnace Ground Granulated Blast Furnace Slag Iron Ore Steel Png 630x543px Furnace Area Basic Oxygen

Source: favpng.com

Blast Furnace Ground Granulated Blast Furnace Slag Iron Ore Steel Png 630x543px Furnace Area Basic Oxygen

Source: favpng.com

The concentrated ore is blended with limestone CaCO 3 and Coke and fed into blast furnace from the top.

Iron Ore To Steel Process Flow Chart Tifom

Source: tifom.unionadfp.org

Iron Ore To Steel Process Flow Chart Tifom

Source: tifom.unionadfp.org

The absorbed carbon remains dissolved in the molten.